Nowt to do with bikes - again

Posted: Fri Nov 25, 2016 7:04 pm

Once again, nothing to do with bikes but I figure there's enough tinkering goes on here that it might be of some interest ......

For anyone who doesn't know, arrow cresting involves painting bands or lines on arrows so they can be identified. It's something that people have done for centuries and if you're handy with a brush, the results can look something like the picture below.

However, to achieve results like that, you're going to need an arrow cresting machine - think something to spin the arrow while you apply the paint. There's not many available and what are cost upwards of £150. I have seen some DIY versions but they generally look like an ill-conceived cobble. Most only support the arrow at the nock end and simply rely on resting it on something part-way along its length which allows the arrow to wander or vibrate - obviously not good.

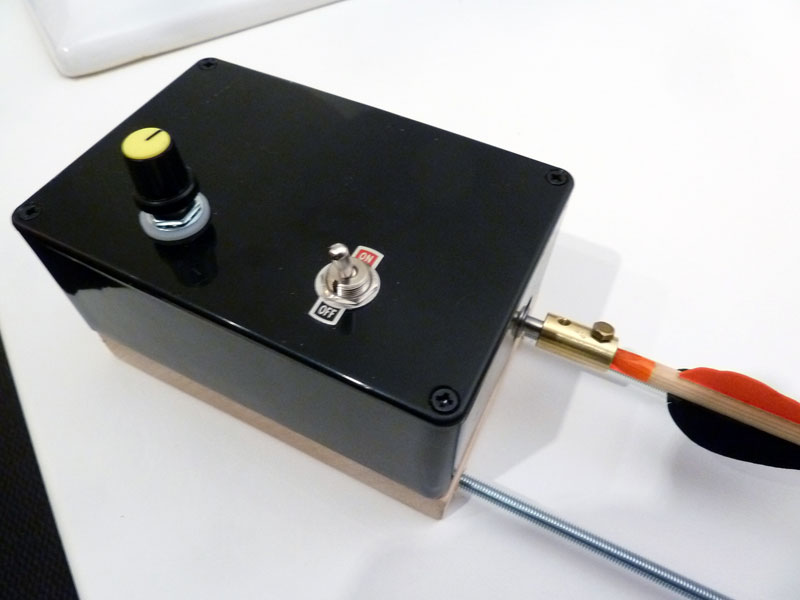

I made a brew and retired to the workshop for a think, returning some time later with this.

I've wired it up with an 18v supply (2 x pp3 in series) and run the power through a speed regulator which allows for anything between 120 rpm and 380 rpm in theory. I'd seen that many DIY versions simply relied on pushing the nock into a small piece of rubber tube on the end of the motor shaft but I thought that would exaggerate any potential for wobble. Instead, I made a liitle 'chuck' with an internal piece that the nock positively engages with.

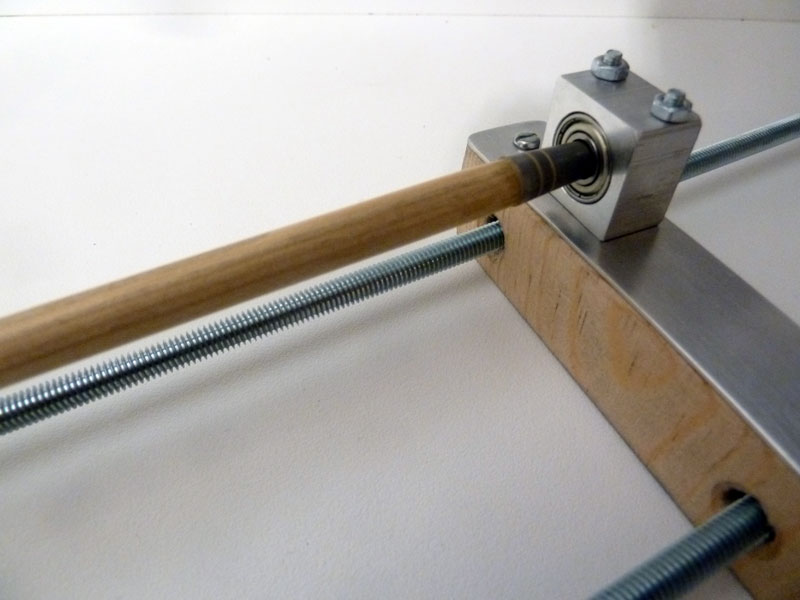

I've used a bearing on the pointy end to hold the arrow securely. You simply locate the nock in the 'chuck', slide the bearing carrier onto the tip, secure it in place with a couple of wing-nuts and you're good to go.

Quite enjoyed myself

For anyone who doesn't know, arrow cresting involves painting bands or lines on arrows so they can be identified. It's something that people have done for centuries and if you're handy with a brush, the results can look something like the picture below.

However, to achieve results like that, you're going to need an arrow cresting machine - think something to spin the arrow while you apply the paint. There's not many available and what are cost upwards of £150. I have seen some DIY versions but they generally look like an ill-conceived cobble. Most only support the arrow at the nock end and simply rely on resting it on something part-way along its length which allows the arrow to wander or vibrate - obviously not good.

I made a brew and retired to the workshop for a think, returning some time later with this.

I've wired it up with an 18v supply (2 x pp3 in series) and run the power through a speed regulator which allows for anything between 120 rpm and 380 rpm in theory. I'd seen that many DIY versions simply relied on pushing the nock into a small piece of rubber tube on the end of the motor shaft but I thought that would exaggerate any potential for wobble. Instead, I made a liitle 'chuck' with an internal piece that the nock positively engages with.

I've used a bearing on the pointy end to hold the arrow securely. You simply locate the nock in the 'chuck', slide the bearing carrier onto the tip, secure it in place with a couple of wing-nuts and you're good to go.

Quite enjoyed myself