Page 1 of 1

The BB Tent Peg Test

Posted: Fri Jul 26, 2013 1:45 pm

by Zippy

So I read up Stu'd semi scientific tent peg test.

http://bearbonesbikepacking.blogspot.co ... -test.html

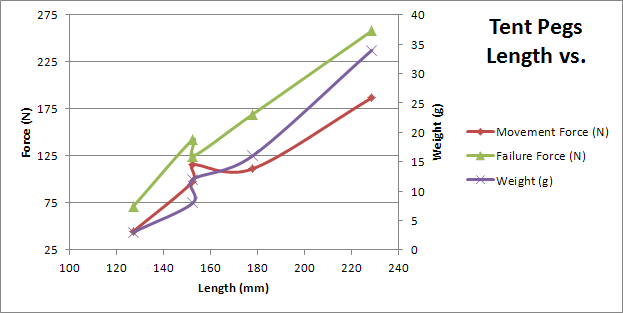

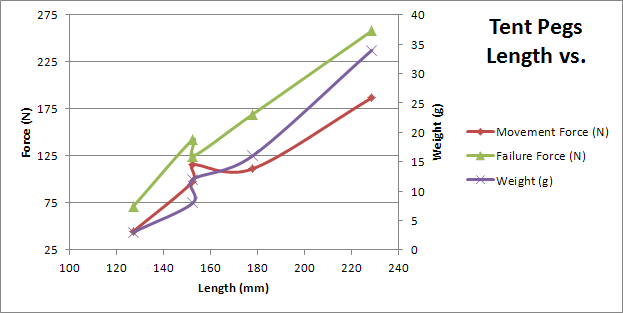

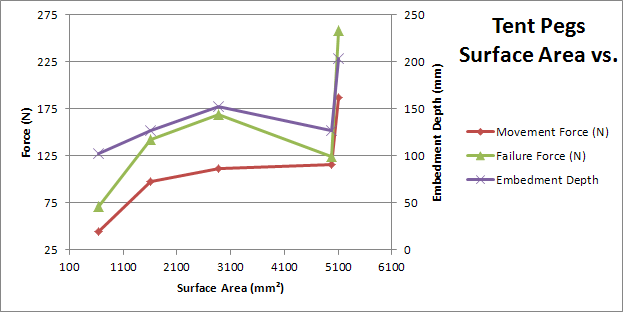

So what I then decided to do, was to tabulate the results and make them metric. I then made excel draw some graphs with respect to Length being the x axis and then looking at how the length affects to weight and various failure forces.

There is a bit more to this than the simple graphs, as it's the surface area of the peg in contact with the ground that's the most critical factor. In essence, the larger the surface area of the peg in contact with the soil giving frictional resistance (particles towards the clay end of the particle size distribution will be best for this and give have higher skin friction than the sand end) which will give the higher resistance. It's pretty much piled foundation designs, but resultant forces have to be resolved as their at an incline, and the force is pulling upwards as opposed to downwards so there's no base bearing support...actually tension foundations aren't the norm in structures but I like using the application

My ten penneth worth.

Re: The BB Tent Peg Test

Posted: Fri Jul 26, 2013 5:45 pm

by Bearbonesnorm

That ^ Zippy is the best bit of geekery we've ever had ... sincere congratulations, fantastic effort

Re: The BB Tent Peg Test

Posted: Fri Jul 26, 2013 7:02 pm

by Ian

Doffs cap...

Re: The BB Tent Peg Test

Posted: Fri Jul 26, 2013 9:53 pm

by Ian

/puts hand up

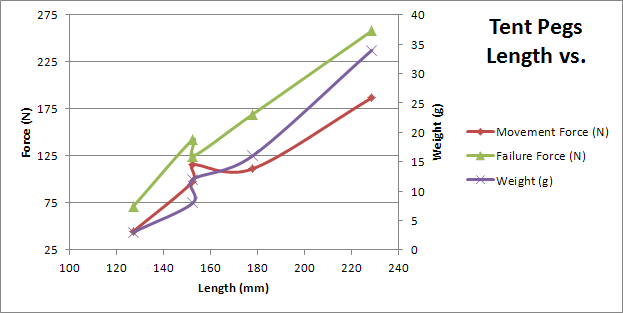

why aren't the lines linear and what's the explanation behind the deviations at 155mm length?

Re: The BB Tent Peg Test

Posted: Fri Jul 26, 2013 9:58 pm

by Ben98

Ian wrote:/puts hand up

why aren't the lines linear and what's the explanation behind the deviations at 155mm length?

There were 2 different pegs at length 155mm and they both had different strengths

Re: The BB Tent Peg Test

Posted: Sat Jul 27, 2013 12:10 pm

by Zippy

Ian wrote:/puts hand up

why aren't the lines linear and what's the explanation behind the deviations at 155mm length?

The two pegs are the Ti Nail and the Alu V, both approx 6" (152.4mm) long according to the photo.

The Ti Nail failed before the Alu V despite being the same length, however the length is one measurement, we also need the other one to get the total surface area in contact with the ground. The round Ti Nail I expect to have a smaller surface area than the V, hence a greater force required to overcome the total friction (capacity = coefficient friction x surface area; assume coeficient of friction pretty much the same, but surface areas different, hence different capacity). The better graph would be surface area in contact with ground vs. failure force and then you'd have a nicer looking linear line!

We can go onto other factors such as the coefficient of friction differences between materials, so a knurled peg would have a greater coefficient of friction and need slightly more force to pull it out. Also, as you get deeper, the ground gets stronger and so friction skin friction numbers get bigger as you go deeper.

To be fair, weight has very little bearing on the results, other the clearly if it was really really really light, the peg itself might fail before contact between the peg and the ground does.

Does that answer your question Ian?

The short answer to the non linear line is that I drew technically the wrong graph

Re: The BB Tent Peg Test

Posted: Sat Jul 27, 2013 5:58 pm

by paul78

I think Zippy is a geotechnical engineer :)

I agree there is no end bearing load as per a pile so resistance is all skin friction with all forces located in the upper parts of the peg as lateral forces try to pull it out.

Much like piled foundations that are gonna have to be developed to enable floating windfarms anchored to the seabed in deeper water.

I expect to see further work modelled in FE software Zippy :)

Re: The BB Tent Peg Test

Posted: Sat Jul 27, 2013 7:12 pm

by Bearbonesnorm

I've just put my anorak on to brave the rain and measure the pegs.

Aluminium shepherd's crook: 6mm diameter

Aluminium stake: 8mm diameter

Ti nail: 4mm diameter

Steel shepherd's crook: 2mm diameter

Aluminium V: 9mm x 9mm x 1.5mm

Re: The BB Tent Peg Test

Posted: Mon Jul 29, 2013 10:19 am

by Zippy

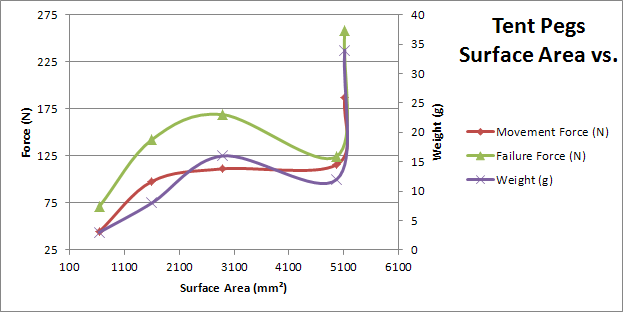

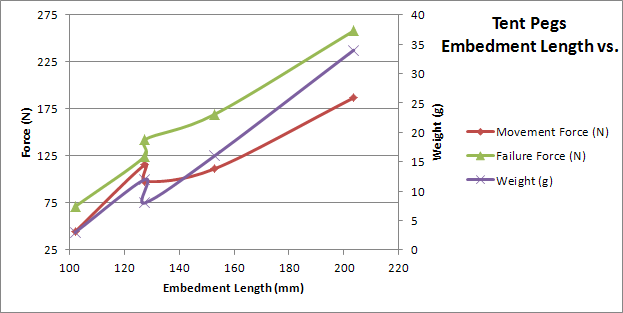

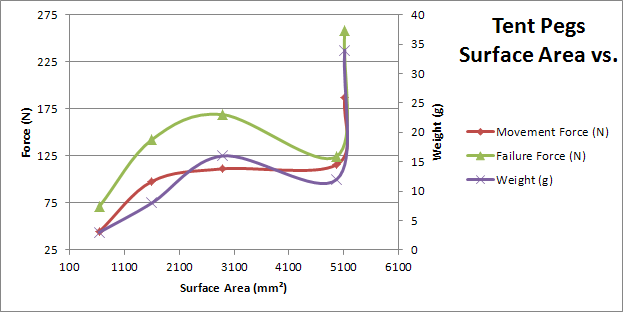

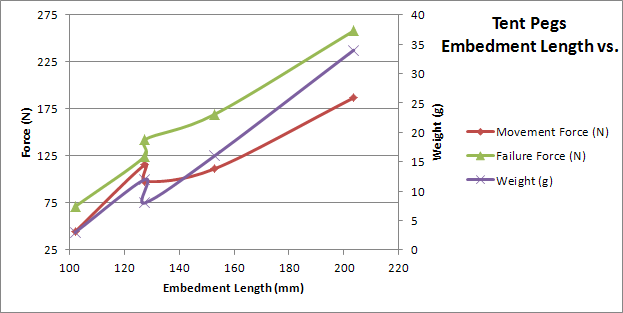

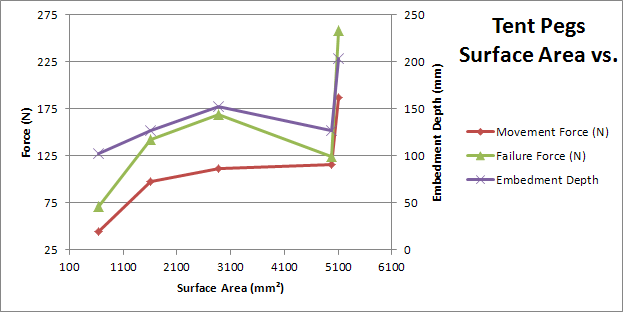

Updated my spreadsheet with Stu's latest measurements to provide the following graphs: I've assumed a 25mm bit of the peg sticking out of the ground. Some er, interesting shape graphs - possible explanations to follow on my lunch break

Following that graph, I've also made this graph to see if it helped...

Re: The BB Tent Peg Test

Posted: Mon Jul 29, 2013 12:35 pm

by Zippy

paul78 wrote:I think Zippy is a geotechnical engineer :)

I agree there is no end bearing load as per a pile so resistance is all skin friction with all forces located in the upper parts of the peg as lateral forces try to pull it out.

Much like piled foundations that are gonna have to be developed to enable floating windfarms anchored to the seabed in deeper water.

I expect to see further work modelled in FE software Zippy :)

Sounds like you're doing some interesting work Paul, actually that's really interesting compared to my substations.

Anyway, onto potential explanations then. I've also drawn another graph. You can also download my scrappy spreadsheet

here.. I was hoping for a nice straight graph, because then I could let people choose there tent peg material (steel, ti, alu etc.) the dimensions and then you could work out from the equation of the line the capacity of the peg in Stu's testing plot

So what we can see is generally that as the surface area increases, the force required to pull the peg out increases, due to the skin friction in the ground, as mentioned earlier. You'll also see, that the embedment depth has a factor on this - for starters this will generally increase the surface area of the peg (x*y, making y greater). The other thing that happens with depth is the ground is more consolidated (squashed) so when analysing ground, it's in simplified terms stronger because of all the ground above squashing it, and will give higher cohesion numbers (in clays) and essentially there's more frictional capacity further down. So you could have say 9999999mm^2 surface area, but this could be say a large wide peg that's 25mm deep, or a narrow peg that's 1metre deep, the 1 metre deep peg would have a greater capacity than the wide peg despite the same surface area.

So really, we should start doing boreholes in Stu's gardens and lab testing the soil

There's a lot more that could be said/analysed, and back to the original post, bigger pegs are better, but deeper is better than wider, not withstanding other factors.

Re: The BB Tent Peg Test

Posted: Mon Jul 29, 2013 1:10 pm

by Bearbonesnorm

Good work Zippy.

So I think in summary it's fair to say either go, short 'n' fat or long 'n' thin ... or long 'n' fat if things are very serious

Re: The BB Tent Peg Test

Posted: Mon Jul 29, 2013 1:26 pm

by Zippy

s8tannorm wrote:Good work Zippy.

So I think in summary it's fair to say either go, short 'n' fat or long 'n' thin ... or long 'n' fat if things are very serious

I think looking at your data, the depth of the peg is more critical...normally coz the top bit of the ground is crap and you start getting into the more consolidated decent ground the deeper you go.

So long and thin is better than short and fat, - unless you hit a rock. But in general depth is king I reckons 8-)

Thanks for experimenting Stu

Re: The BB Tent Peg Test

Posted: Mon Jul 29, 2013 10:16 pm

by Ian

deeper is better than wider

Said the actress to the bishop